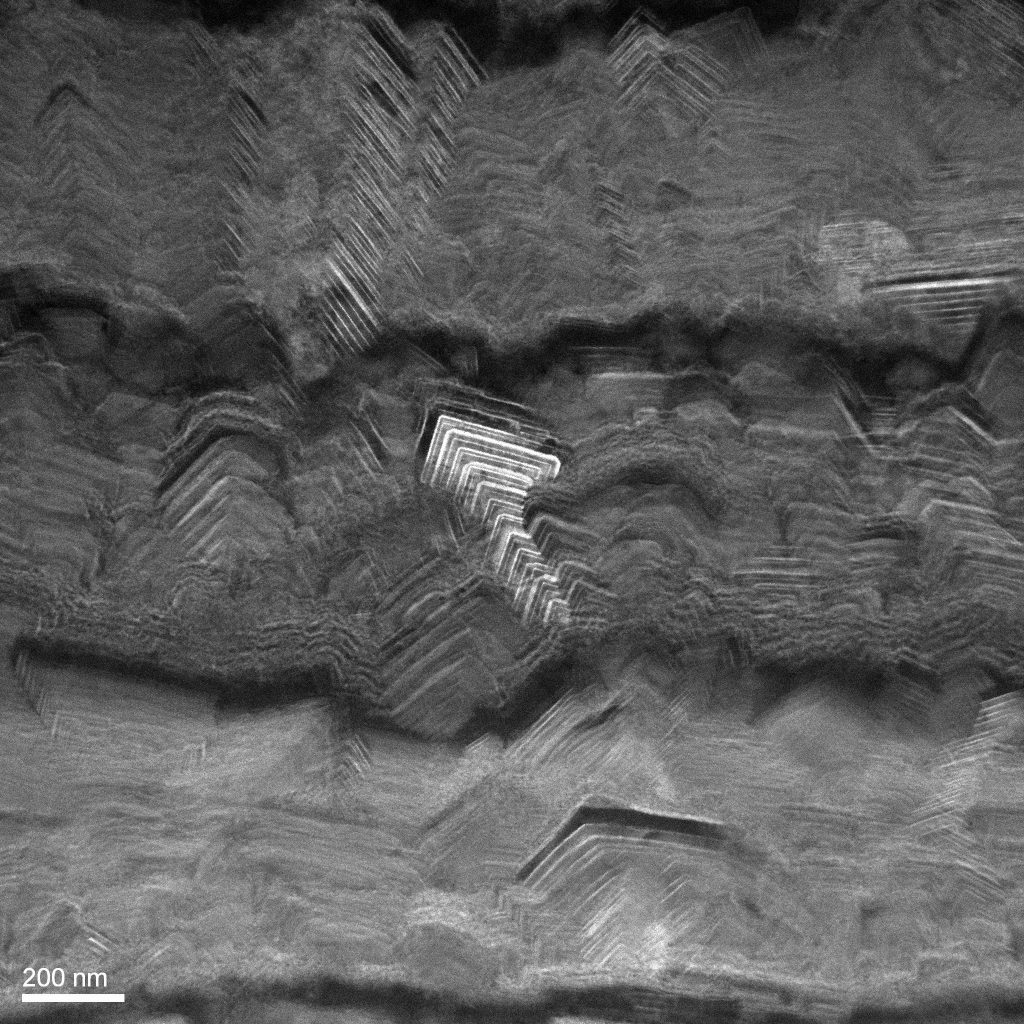

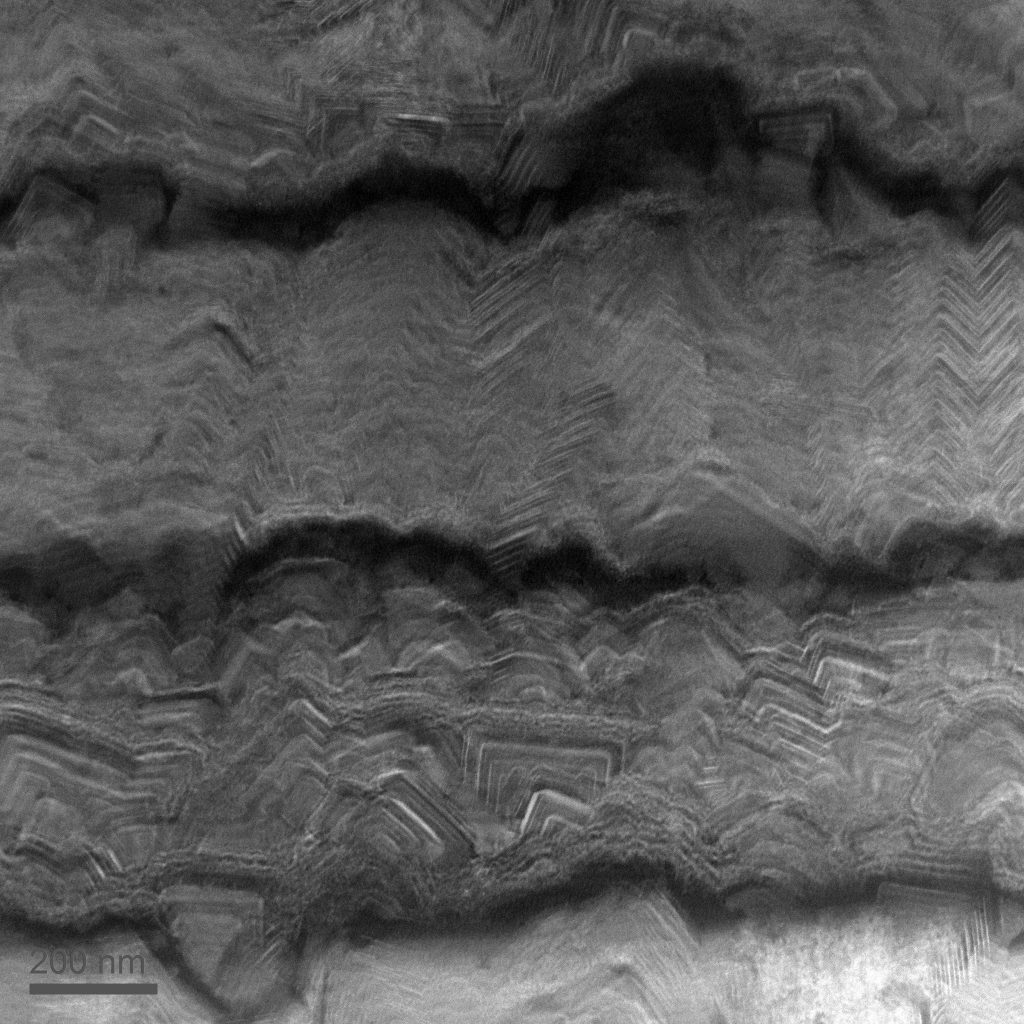

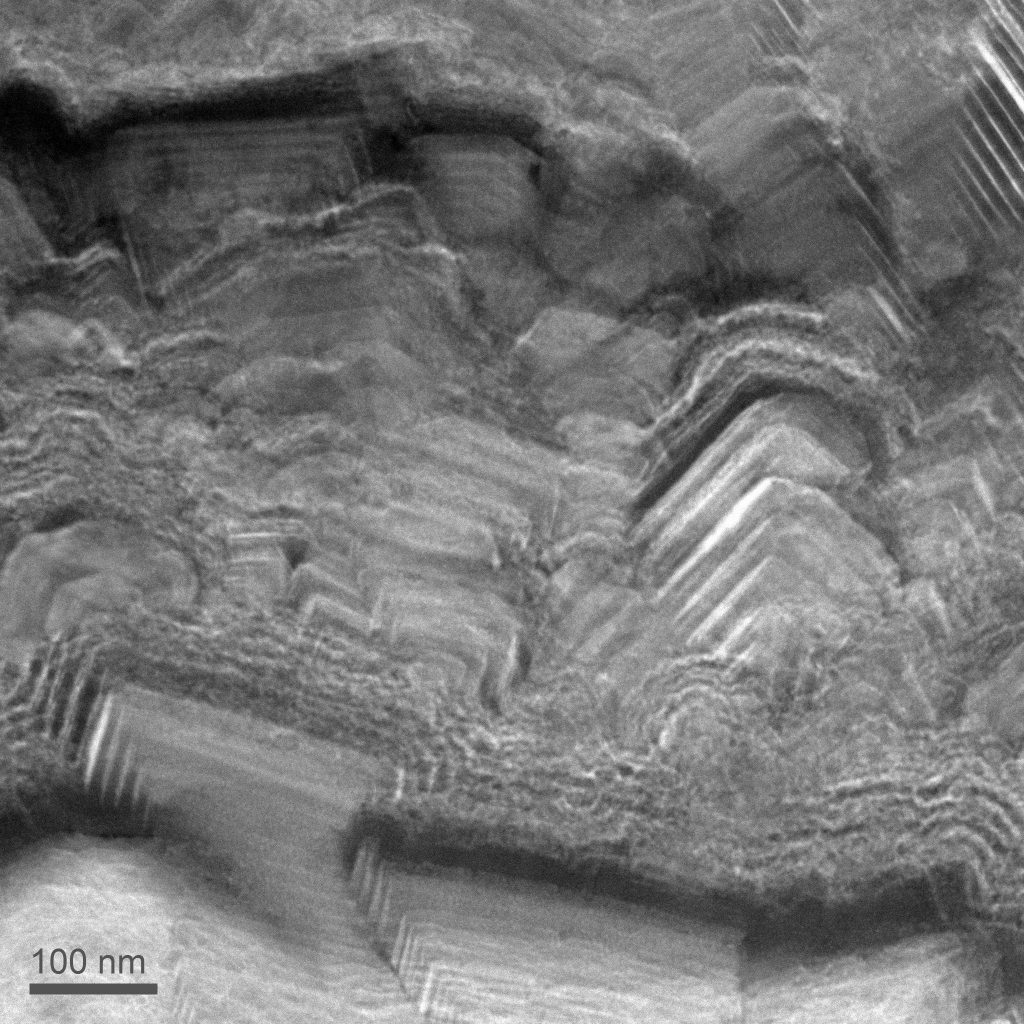

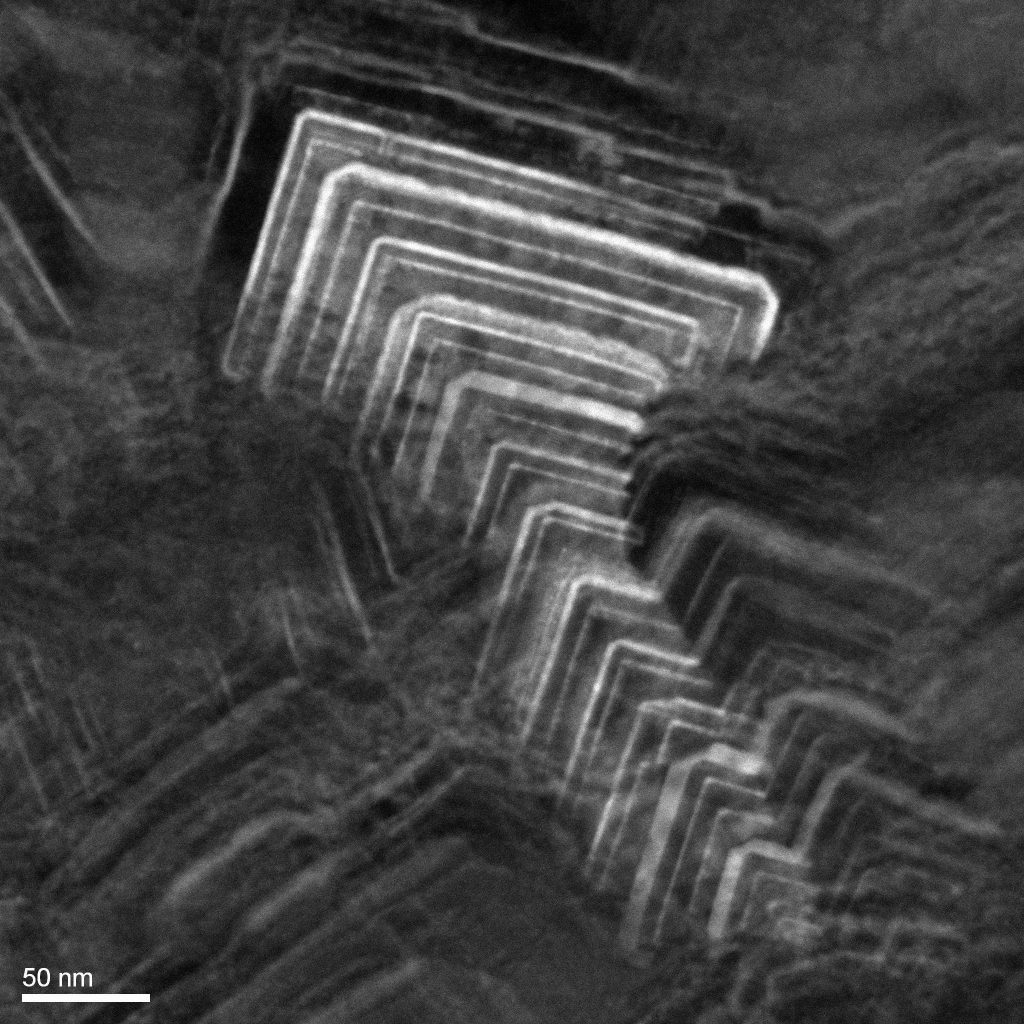

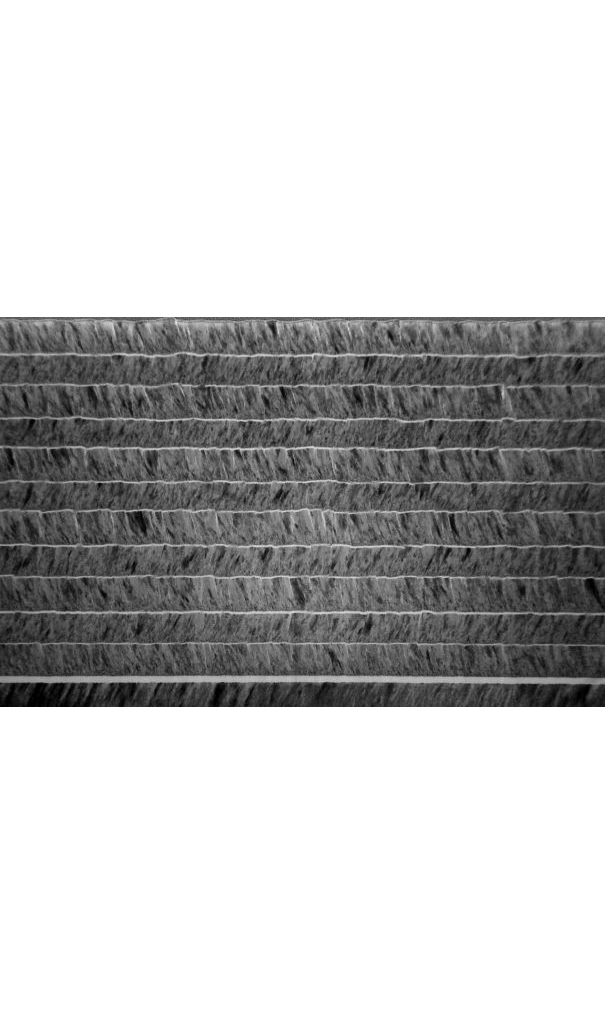

Hard and tough nanoceramics with six levels of hierarchy synthesized by a CVD process

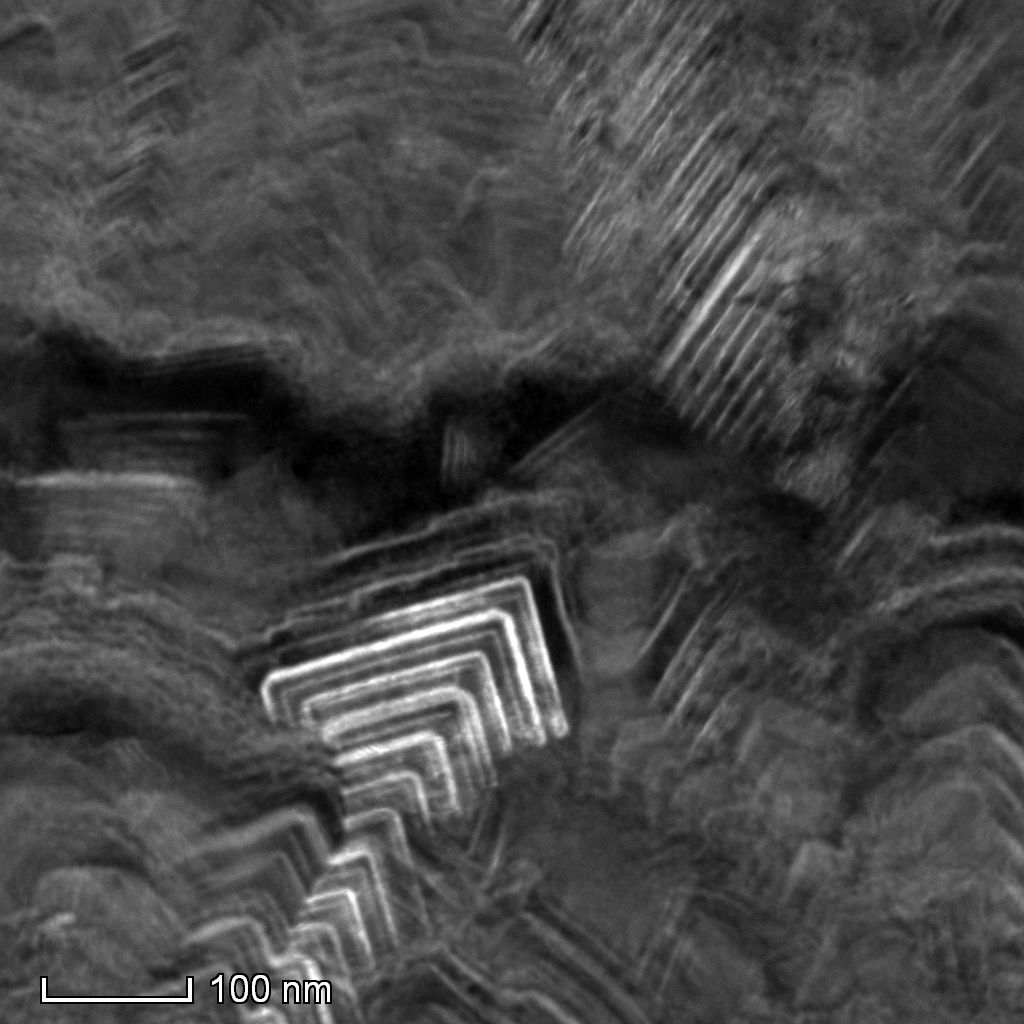

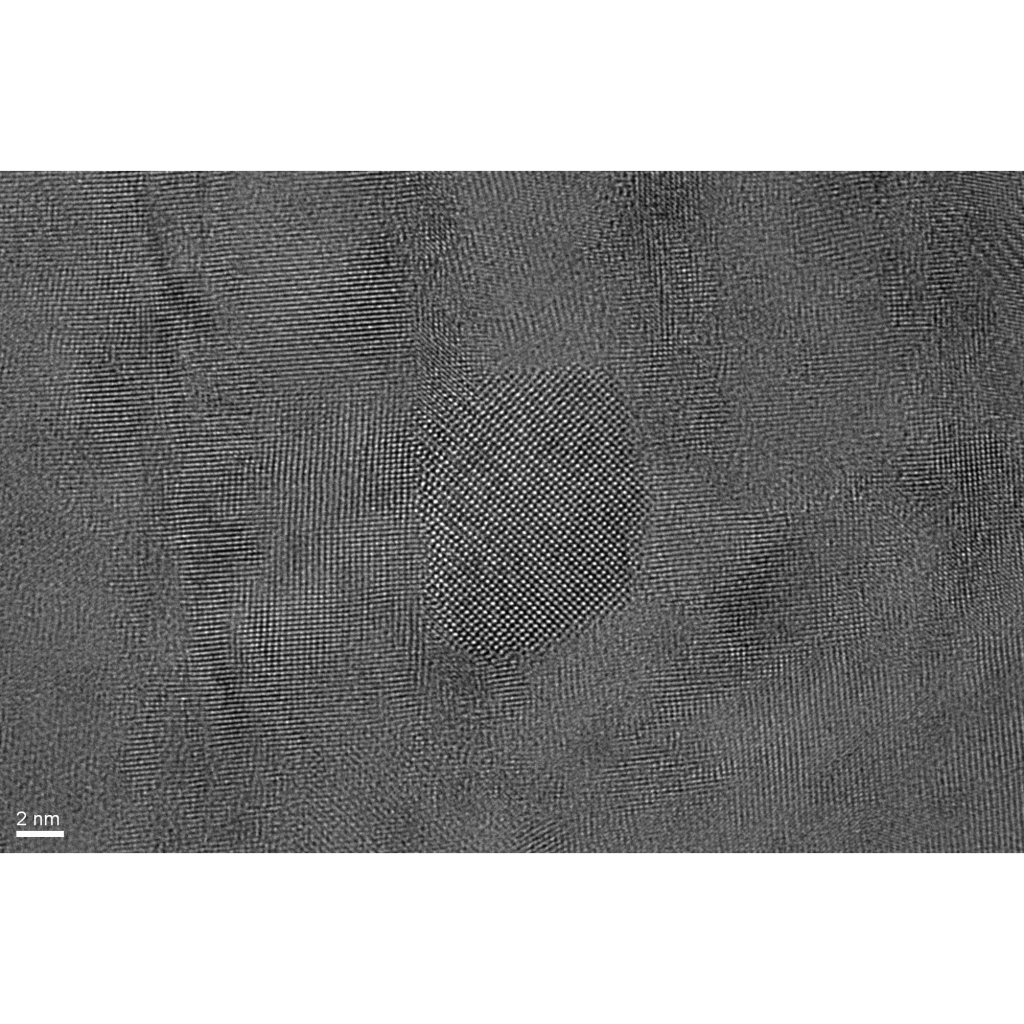

Chemical vapour deposition was used to grow a hard and simultaneously tough TiAlN nanostructure with six levels of hierachy. By using two variants of gaseous precursors, an irregularly arranged hard and tough multilayer stack was deposited, consisting of hard sublayers with herringbone micrograins, separated by tough interlayers with spherical nanograins. Micro- and nanomechanical testing indicated intrinsic toughening mechanisms mediated by five types of length scale-specific interfaces, resulting in intergranular, transgranular and cleavage fracture modes with zigzag-like crack patterns at multiple levels of hierarchy.

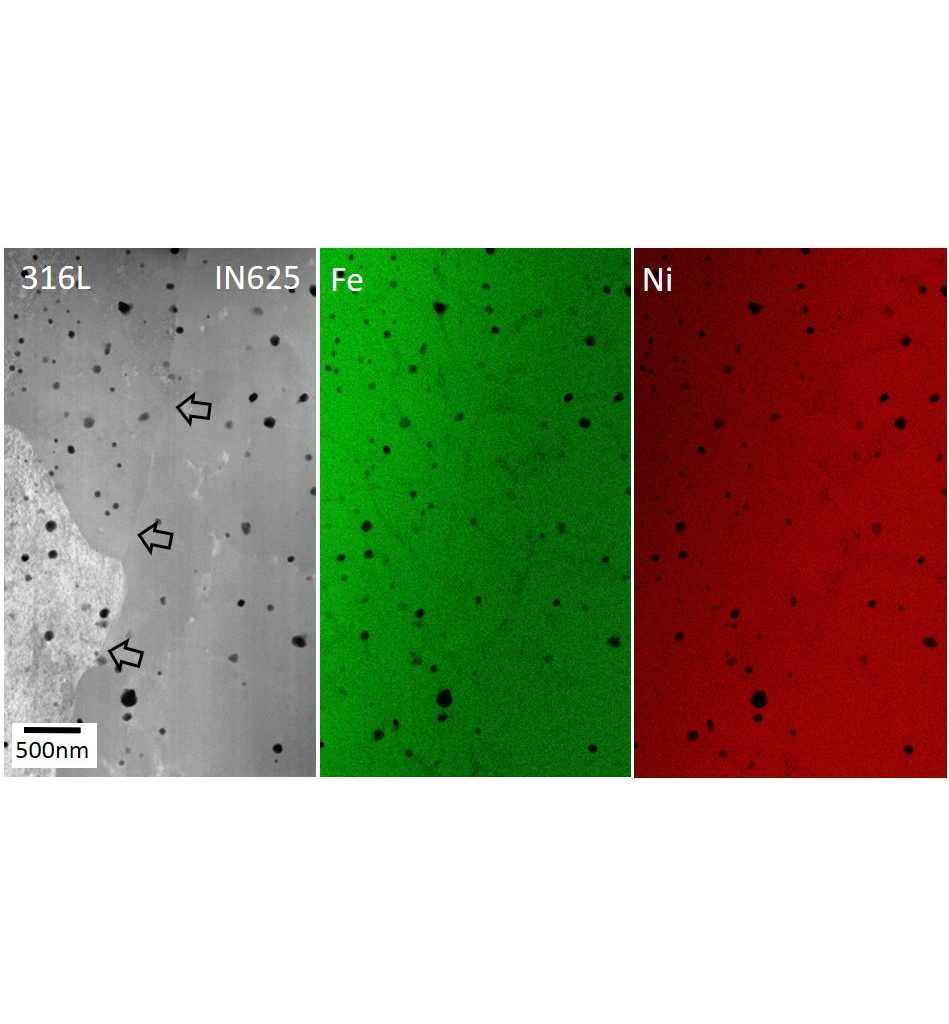

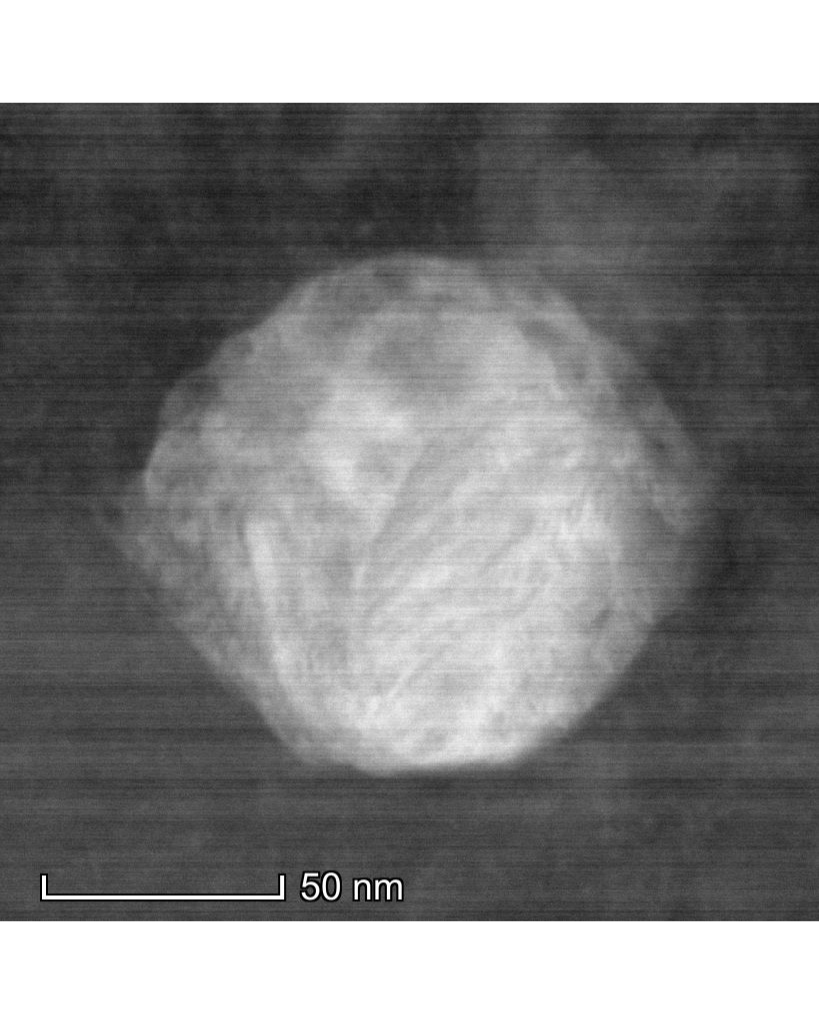

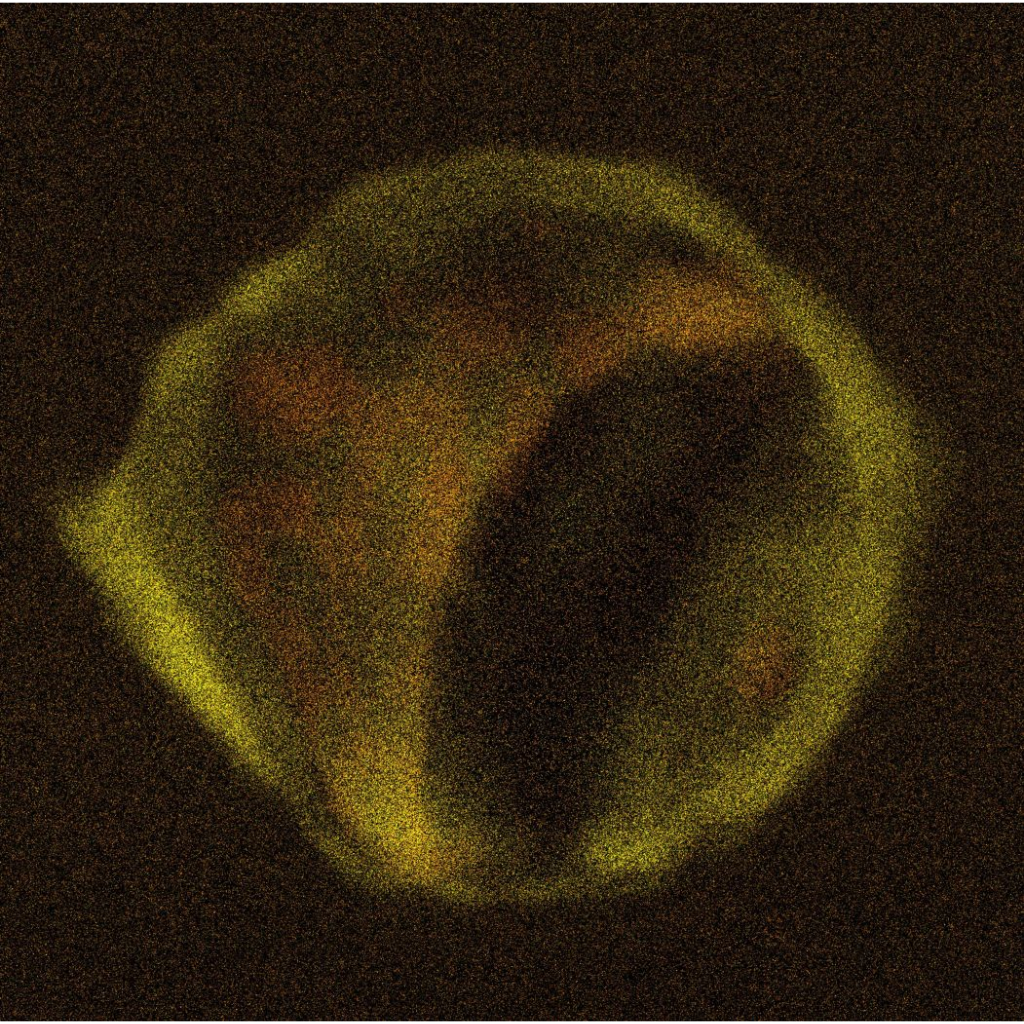

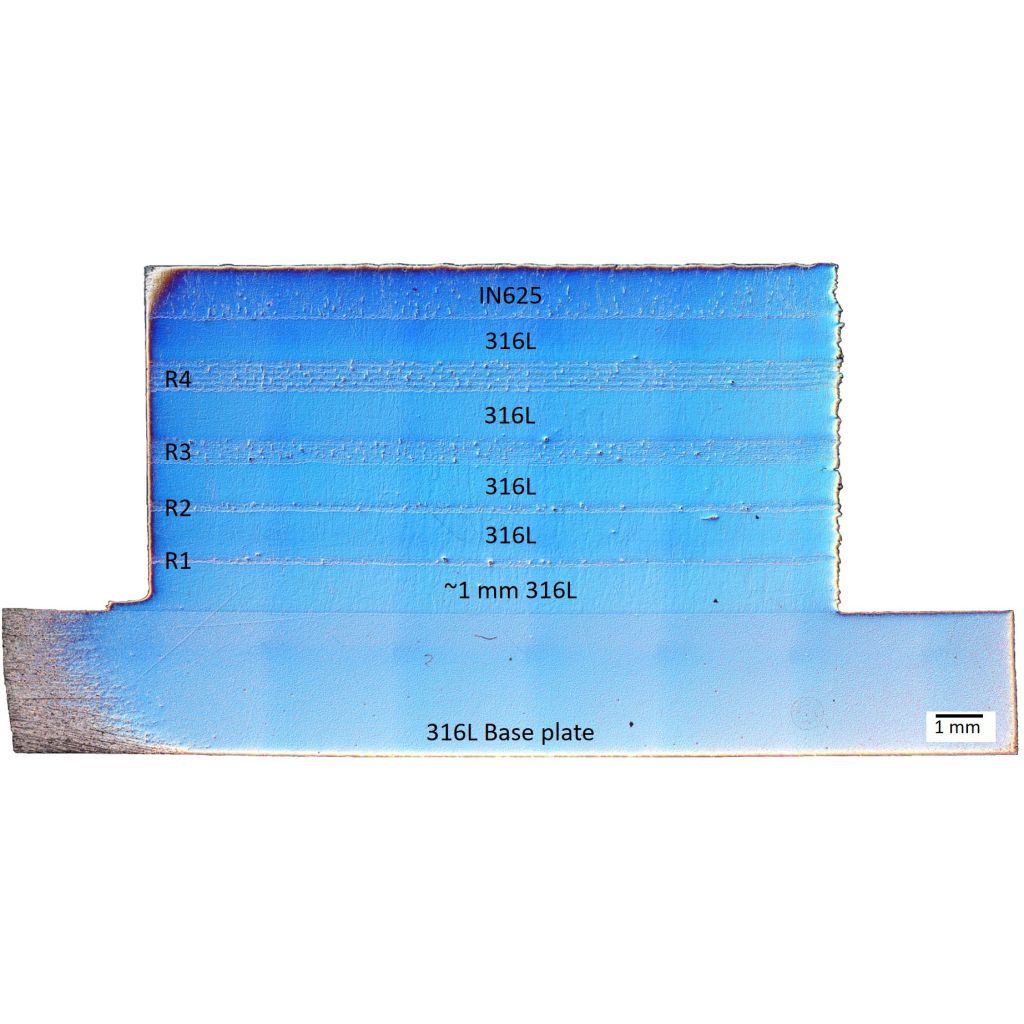

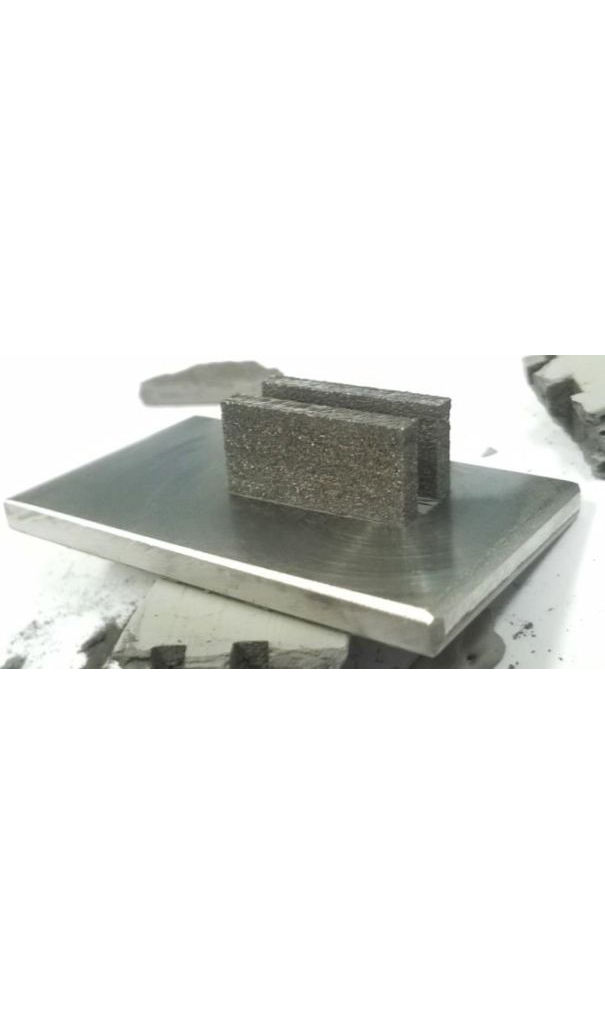

Inconel-steel multilayer manufactured by powder bed fusion

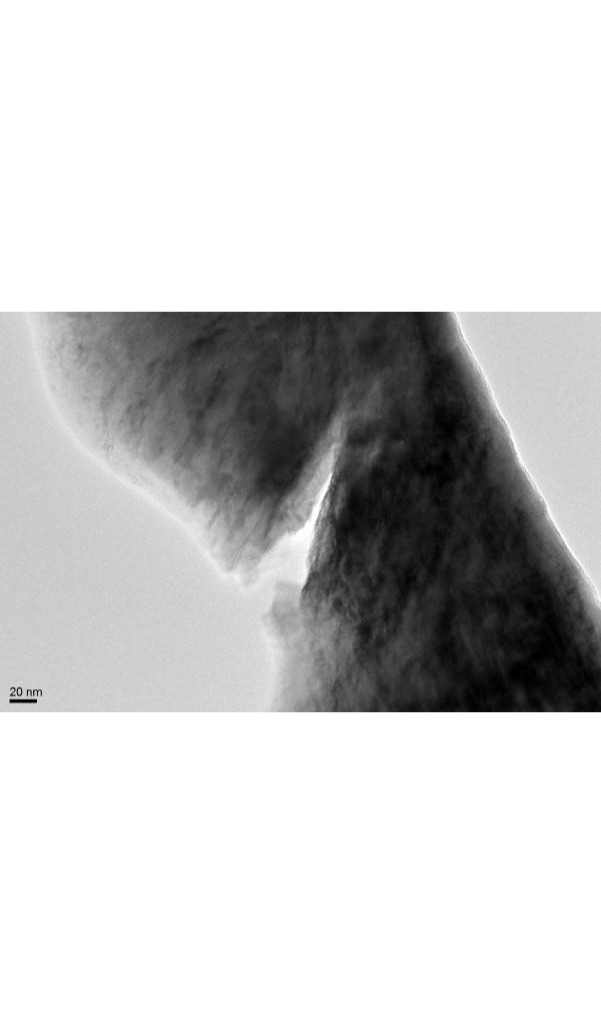

Additive manufacturing utilizing liquid dispersed metal powder bed fusion was used to fabricate a multilayered structure based on alternating Inconel 625 alloy and 316L stainless steel layers on a 316L base plate. Our analytical techniques revealed rather sharp compositional, structural and microstructural boundaries between alternating approx. 60 µm thick alloy sub-regions as well as unique microstructures at macro, micro- and nano-scales.

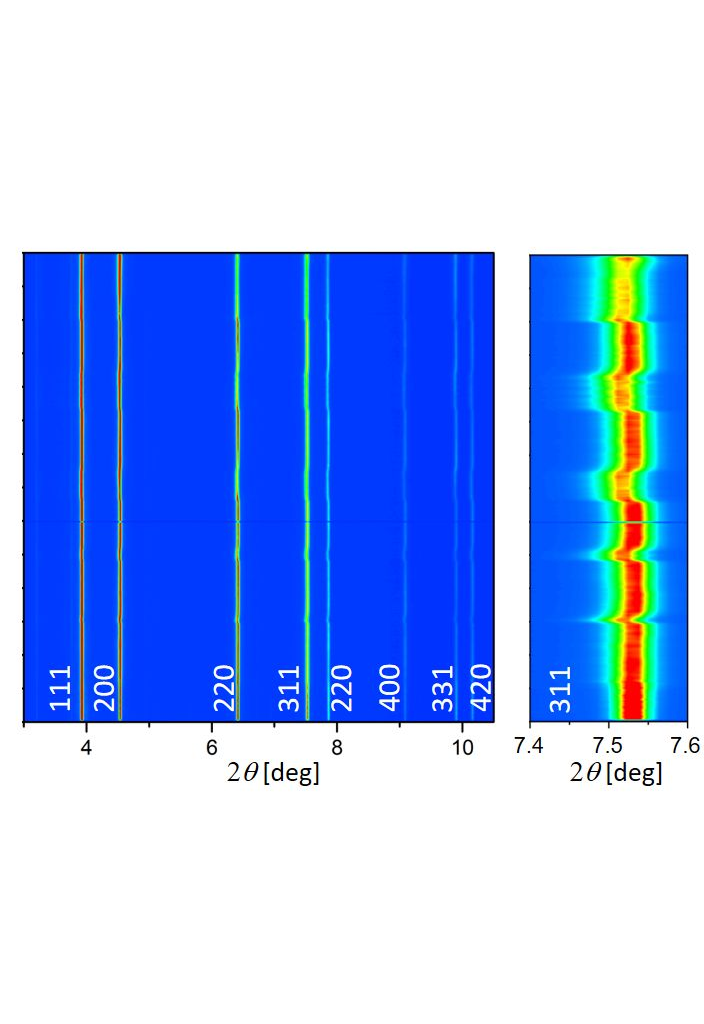

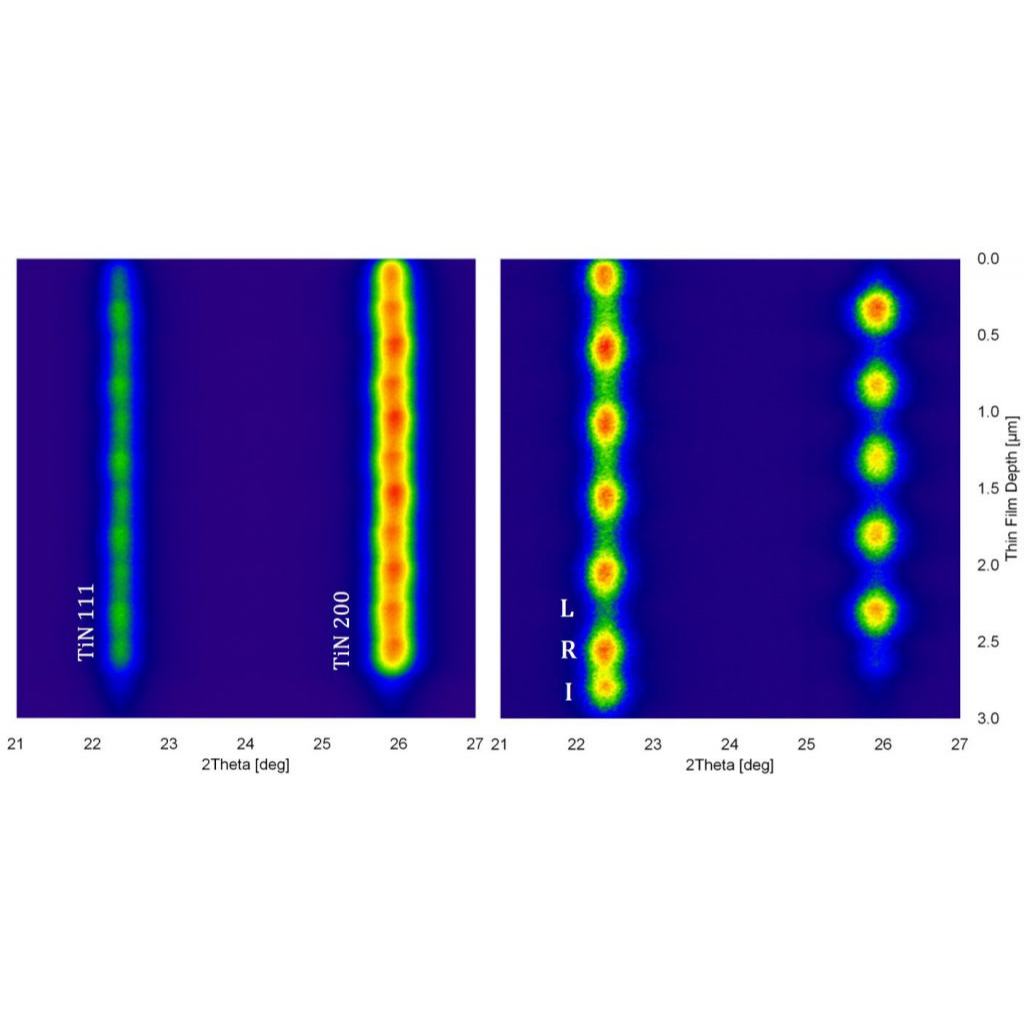

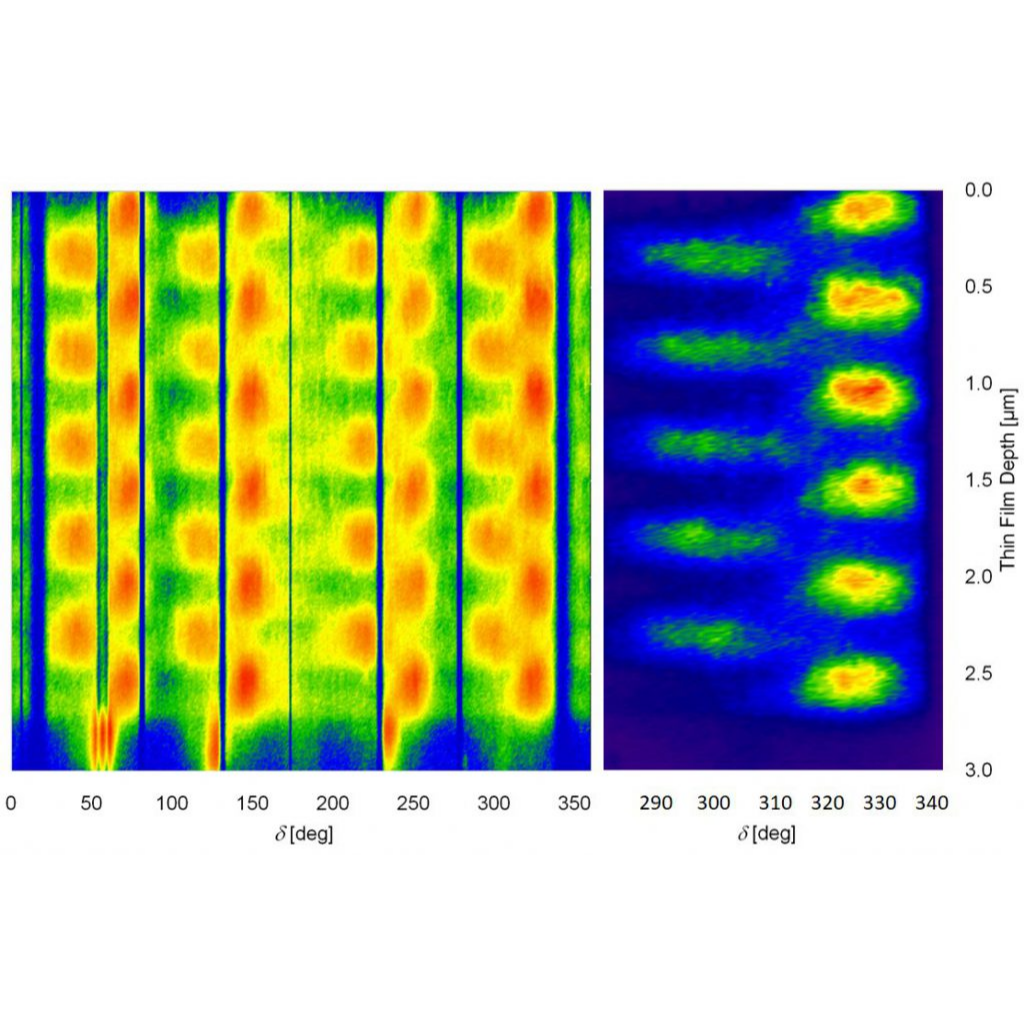

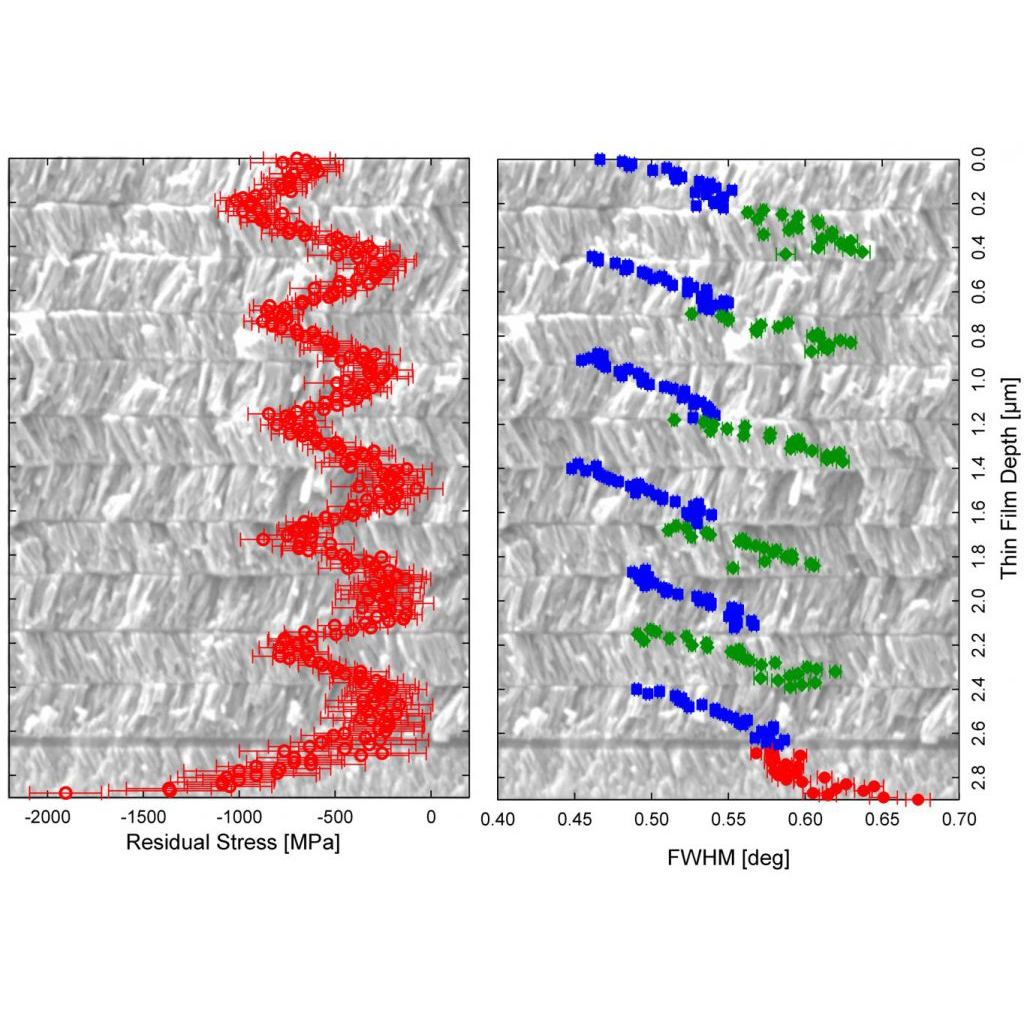

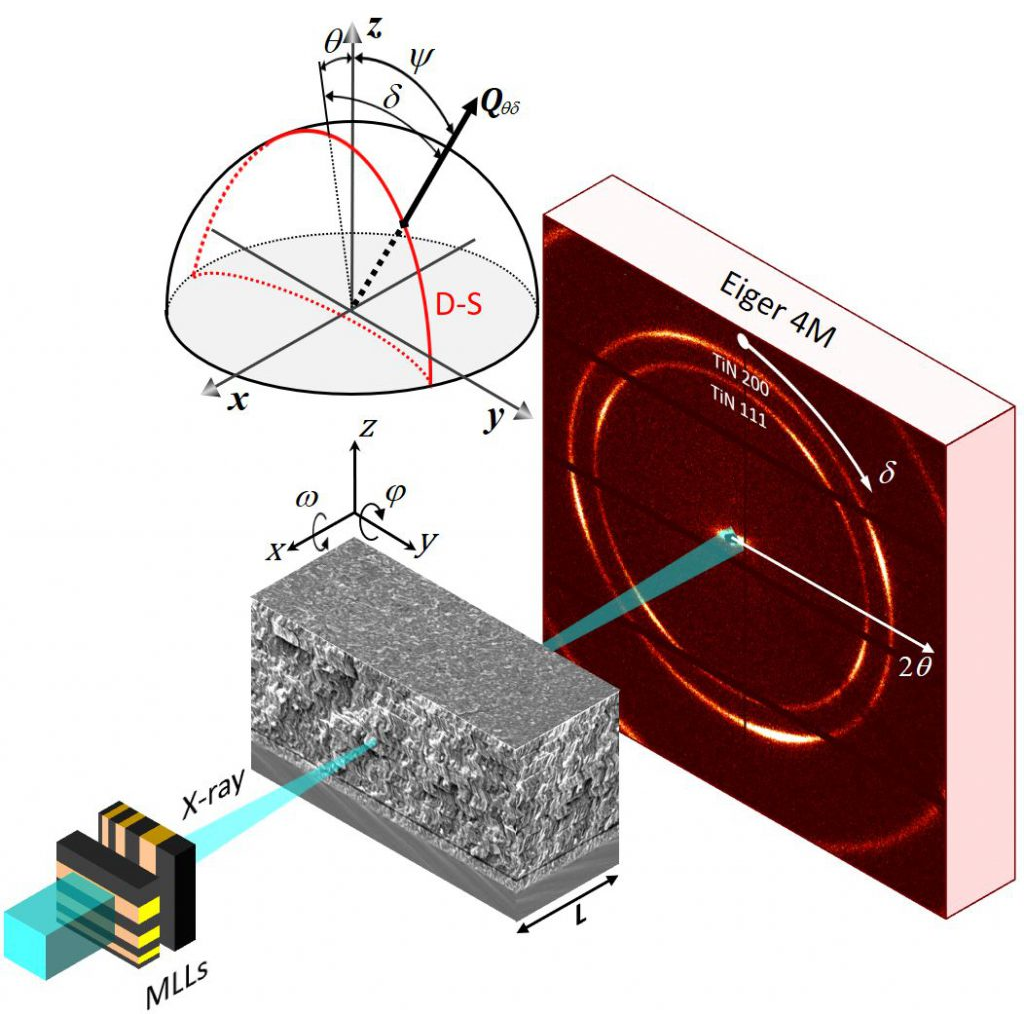

Cross-sectional X-ray nanodiffraction characterization of microstructure and stress gradients

Since 2009, cross-sectional X-ray nanodiffraction on thin films, operating with X-ray beams with a diameter down to approx. 25 nm was developed in collaboration with our partners from the synchrotron facilites ESRF and DESY. The approch allows for the characterization of a complete fingerprint of phases, microstructure and residual stress gradients in thin films with great spatial resolution, while still capturing representative sample volumes.